Professional Custom Boxes for Packaging & Branding

-

Custom Sizes

-

Strong Material

-

Full Colour Print

-

Luxury Finishes

-

Fast Production

-

Eco-Friendly Boxes

-

UK Delivery

-

Affordable Price

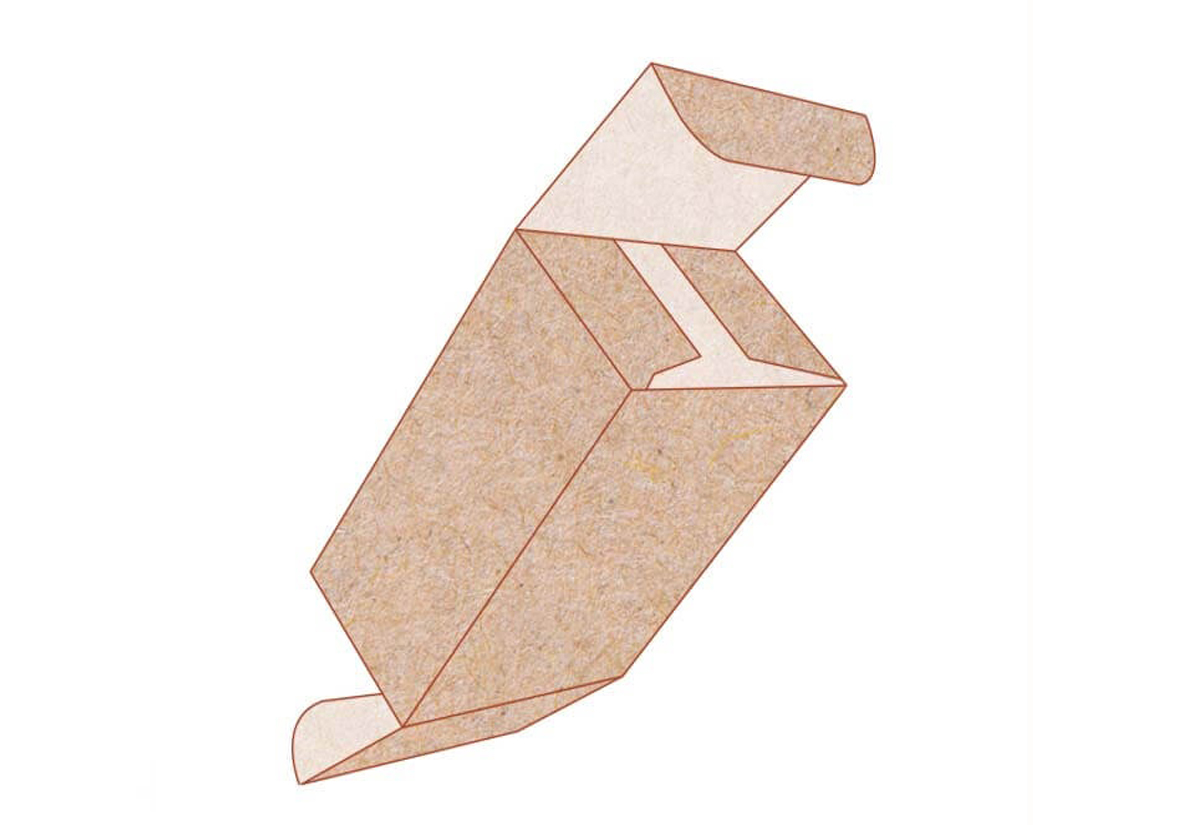

Personalized Reverse Tuck End Made For Your Brand

Optimize your packaging with our custom reverse tuck end boxes. Designed with tuck flaps at opposite ends, these boxes provide easy assembly and secure closure, making them ideal for retail, food packaging, and promotional products.

Easy Assembly with Secure Reverse Tuck Flaps

Our reverse tuck end boxes feature tuck flaps on opposite ends of the box, allowing for quick and tool-free assembly while ensuring the contents stay securely inside. This design enhances efficiency without compromising on protection.

- • Tuck flaps at opposite ends for secure closure

- • Fast, easy, and glue-free assembly

- • Suitable for retail packaging, food products, and more

→ Streamline your packaging process with functional and reliable boxes.

Customisable to Reflect Your Brand Identity

Each reverse tuck end box is tailored to your product dimensions and branding needs. Choose from vibrant printing options and premium finishes to create packaging that stands out and supports your brand.

- • High-quality CMYK and Pantone printing with matte, gloss, or soft-touch finishes

- • Optional embossing, foil stamping, and spot UV effects

- • Eco-friendly materials and sustainable inks available

→ Deliver packaging that’s both functional and visually appealing.

Low MOQ & Fast UK Shipping

Whether you require small quantities or large production runs, our reverse tuck end boxes offer flexible minimum order sizes and quick turnaround. We ship nationwide with full support from design to delivery.

- • Minimum order starts at 50 units

- • Fast production with tracked UK-wide shipping

- • Complimentary dieline creation and 3D mockups included

→ Get your reliable packaging delivered on time and on brand.

Why Choose Our Reverse Tuck End Boxes?

Trusted by businesses across retail, food, and promotional sectors, our reverse tuck end boxes provide efficient, secure packaging solutions that protect products and enhance brand image.

- • Secure tuck flap closure on opposite ends

- • Easy to assemble and durable during transit

- • Recyclable and eco-friendly materials available

→ Choose packaging that balances practicality with professional presentation.

Request your free quote for reverse tuck end boxes today and let us help you create packaging that works as hard as your products.

Vibrant Boxes Packaging

Get vibrant, sharp colors with our professional boxes printing.

Lightweight Custom Boxes

Keep your boxes packaging lightweight without losing protection.

Eco-Friendly Custom Boxes

Choose eco-friendly boxes printing with recyclable materials.

Why Choose Our Packaging Boxes?

Our custom boxess are designed to help your brand, business, or personal projects stand out. Printed on high-quality vinyl with vibrant, long-lasting colors, our boxess are durable, waterproof, and scratch-resistant. Whether you need custom logo boxess, die-cut boxess, or personalized designs for events, our boxes printing service ensures professional results every time.

How To Order Custom Printed Packaging Boxes

Learn how easily you can design and create custom boxess with BoxUp.

Explore

Select your custom box, retail display or packaging accessory to get started.

Choose

Explore standard sizes and quantities to view pricing and start your design.

Design

Upload your artwork or create your own design using our templates.

Order

We’ll review your file, follow up if needed, and bring your vision to life.

Why You Choose Us?

We provide high-quality custom label printing to help your brand stand out with vibrant designs and lasting impact.Frequently Asked Questions

Eco-Friendly Printing

We believe great printing shouldn’t harm the planet. That’s why our eco-friendly labels are made using recyclable materials and sustainable inks — helping your brand stay responsible without losing its premium look.

Quick Turnaround

Need labels in a hurry? Our efficient print process ensures fast production and delivery without compromising on quality. Perfect for brands on a tight deadline.

Fair & Honest Pricing

No hidden fees, no confusing extras — just transparent, affordable rates for every order. You’ll know exactly what you’re paying for, and you’ll always get more value than expected.